Biomass waste is no longer viewed solely as an agricultural or industrial byproduct. Through controlled thermochemical conversion, it becomes a functional carbon resource with measurable environmental and economic value. A charcoal making machine provides a structured pathway for transforming dispersed organic residues into stable, energy-dense solids, while simultaneously recovering heat and combustible gases for auxiliary use.

Biomass Feedstock Characteristics and Conversion Logic

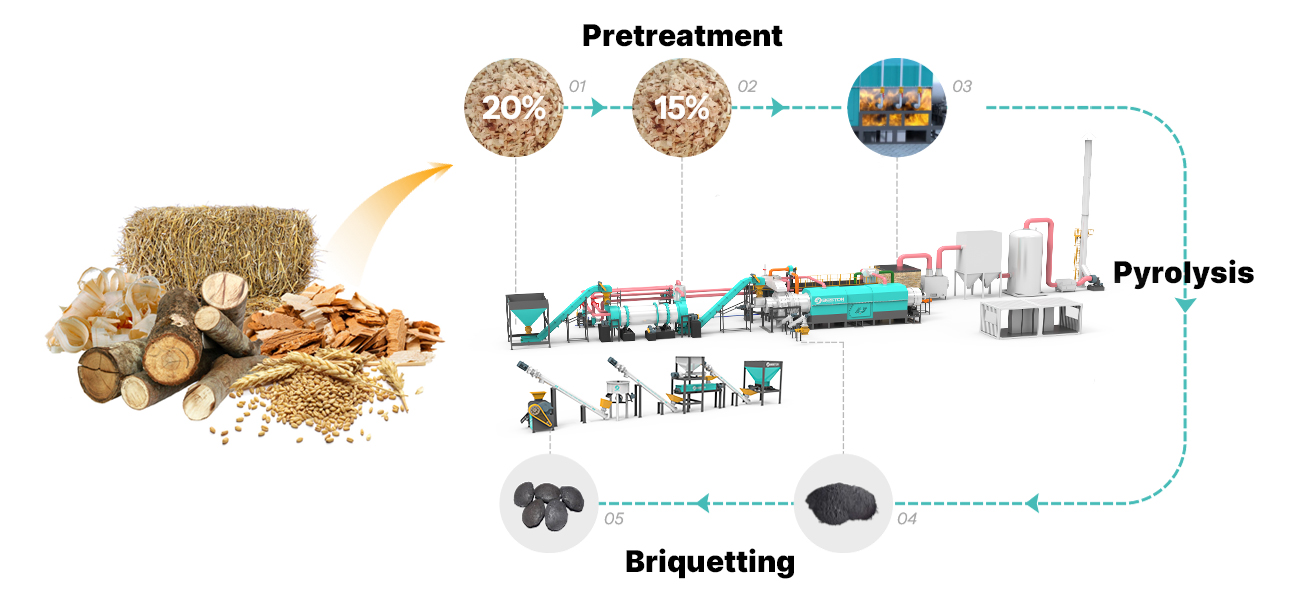

Biomass waste encompasses a heterogeneous range of materials, including crop residues, forestry offcuts, and food-processing byproducts. These materials share a high volatile content and complex lignocellulosic structure. During pyrolytic treatment from rice husk charcoal machine, long-chain polymers decompose into fixed carbon, condensable vapors, and non-condensable gases. The conversion efficiency depends on particle size uniformity, moisture content, and thermal residence time. Proper pretreatment and feedstock classification are therefore decisive factors in ensuring consistent output quality and predictable carbon yield.

Thermochemical Processing Inside the Charcoal Making Machine

At the core of the system lies oxygen-limited carbonization. Biomass is gradually heated within a sealed reactor, preventing direct combustion while enabling molecular rearrangement. Hemicellulose decomposes first, followed by cellulose and lignin at elevated temperatures. The result is a porous carbon matrix with enhanced adsorption potential and improved calorific value. Advanced configurations integrate automated temperature regulation, pressure balancing, and continuous discharge mechanisms, reducing manual intervention and thermal losses. Then use a charcoal briquette machine can make different size of charcoal.

Material-Specific Adaptation and Equipment Configuration

Different biomass streams demand tailored process parameters. For example, a rice husk charcoal machine addresses the high silica content of rice husks, requiring abrasion-resistant linings and optimized ash handling. In contrast, wood-based residues emphasize structural carbon retention and pore development. Modular designs within a biomass pyrolysis plant for sale allow operators to adapt reactor geometry and heating profiles according to feedstock variability, improving operational resilience across seasons.

Value Creation Through Carbon Utilization Pathways

The solid output serves multiple downstream applications. As a soil amendment, carbonized biomass enhances cation exchange capacity and long-term carbon sequestration. In industrial contexts, densification via a charcoal briquette machine converts loose char into standardized fuel units with stable combustion behavior. For investors evaluating a biochar machine for sale, the appeal lies in diversified revenue streams, ranging from agricultural inputs to metallurgical reductants and environmental remediation media.

System Integration and Operational Sustainability

Modern charcoal production is no longer an isolated process. Heat recovery units capture excess thermal energy, while combustible pyrolysis gas is redirected to sustain reactor heating. This closed-loop configuration minimizes external fuel demand and reduces net emissions. Automated monitoring systems further stabilize operations, ensuring compliance with environmental thresholds and extending equipment service life. The result is a scalable, technically coherent solution for converting biomass waste into a commercially viable carbon product.

By aligning material science principles with engineered thermal systems, biomass waste repurposing evolves from disposal management into a structured industrial process. The charcoal making machine stands at the center of this transition, translating low-value organic residues into functional carbon assets with long-term applicability.