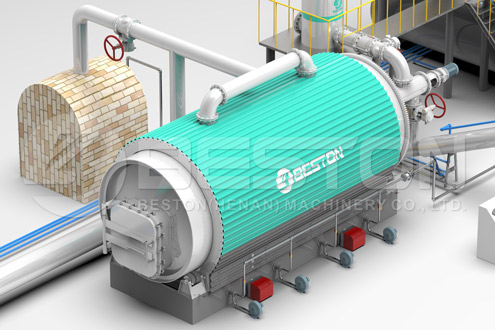

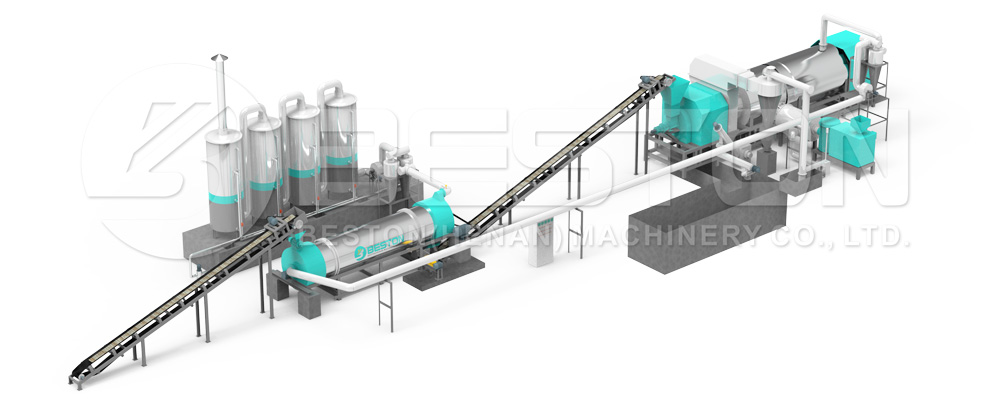

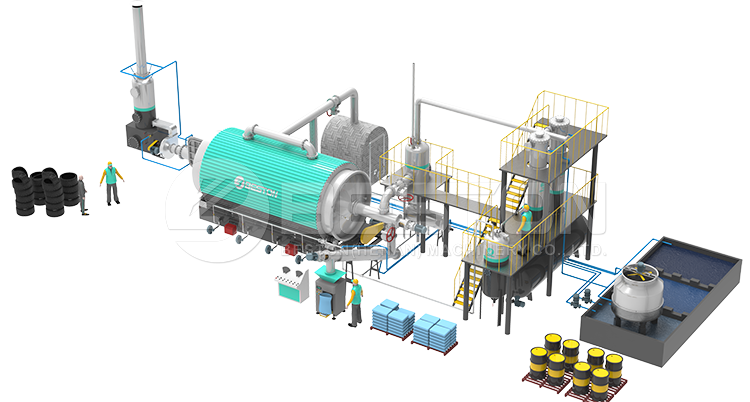

A pyrolysis plant majority recycles wastes into new valuable and profitable products in the market. They can be used to recycle hazardous materials to produce bio-oil, and carbon black for use or selling. When you are in need of a pyrolysis plant or machine, you need to look for the best manufacturers that serve your needs. Some of the key things to have in mind when looking for the best manufacturers are as explained below.

Do research on the quality of machines they produce. A good manufacturer will always have good reviews and positive feedback from their customers. Read through various reviews and see the most mentioned manufacturer for their good and quality machines. We also have independent online reviewers. These are good for your research. Go through their reviews. It will help you make an informed decision.

Look out for features like environmental safety and energy efficiency when in use as well as the machine’s safety. A good manufacturer will take these into consideration when making their machines. The manufacturer should be assured of their safety at all times. A safe machine is easy to operate and demands less of the user. Go for a machine that is not complicated to use, this way you are sure of your protection. The manufacturer should have in mind the effect of the machine on the environment. Recycling main goal is to reduce pollution so the machine the plant produces should ensure it is eco-friendly enough both for the users and what surrounds them.

A perfect pyrolysis plant should be able to make a machine that is energy efficient. You do not want a machine that runs your pocket dry as you try to make a business out of it. Some machines are good enough in that they produce some combustible gases during processing that it can reuse to run itself. This saves you from costs that are too high. Some machines consume less fuel for a huge task.

Consider the cost of pyrolysis plant. This information can be easily obtained from the various catalogs of various manufacturers. You can also ask for referrals from businesses friends who have had an interaction with these manufacturers before. As you assess the prices, let quality be your number one consideration. Do not compromise on it. You can do further research online to see what there is in the market and how much it costs. See there recommendations to know what is most suitable for you. Comparison gives the best idea that you can use while negotiating for the selected machine.

Finally, choose a reliable manufacturer to buy your equipment from. You do not have to limit yourself to a local manufacturer. You can search for other countries for the best product, such as the continuous pyrolysis plant. A good pyrolysis plant manufacturer will have plenty of experience, good customer relation, and a great reputation. Check their background before you engage them. Your research could get a high quality pyrolysis machine at an affordable price that was not on offer in your own country.