Introduction

In the ongoing quest for sustainable solutions to manage waste and generate renewable energy, pyrolysis technology has emerged as a significant player. Pyrolysis plants, which convert waste materials into valuable products like oil, gas, and char, are gaining attention worldwide. However, one of the critical aspects that potential investors and stakeholders need to consider is the cost of setting up and operating a pyrolysis plant. This comprehensive blog aims to delve into the various factors influencing the cost of a pyrolysis plant and provide a detailed analysis to help you make informed decisions.

What is Pyrolysis?

Before diving into the costs, it’s essential to understand what pyrolysis is. Pyrolysis is a thermochemical decomposition process that occurs in the absence of oxygen. It breaks down organic materials into simpler compounds, typically resulting in three main products: bio-oil, syngas, and biochar. These products can be used in various applications, including fuel, electricity generation, and soil enhancement.

Types of Pyrolysis Plants

- Batch Pyrolysis Plants: The pyrolysis plant operates in cycles or batches. They are typically used for smaller operations and have lower upfront costs but may incur higher operating costs due to downtime between batches.

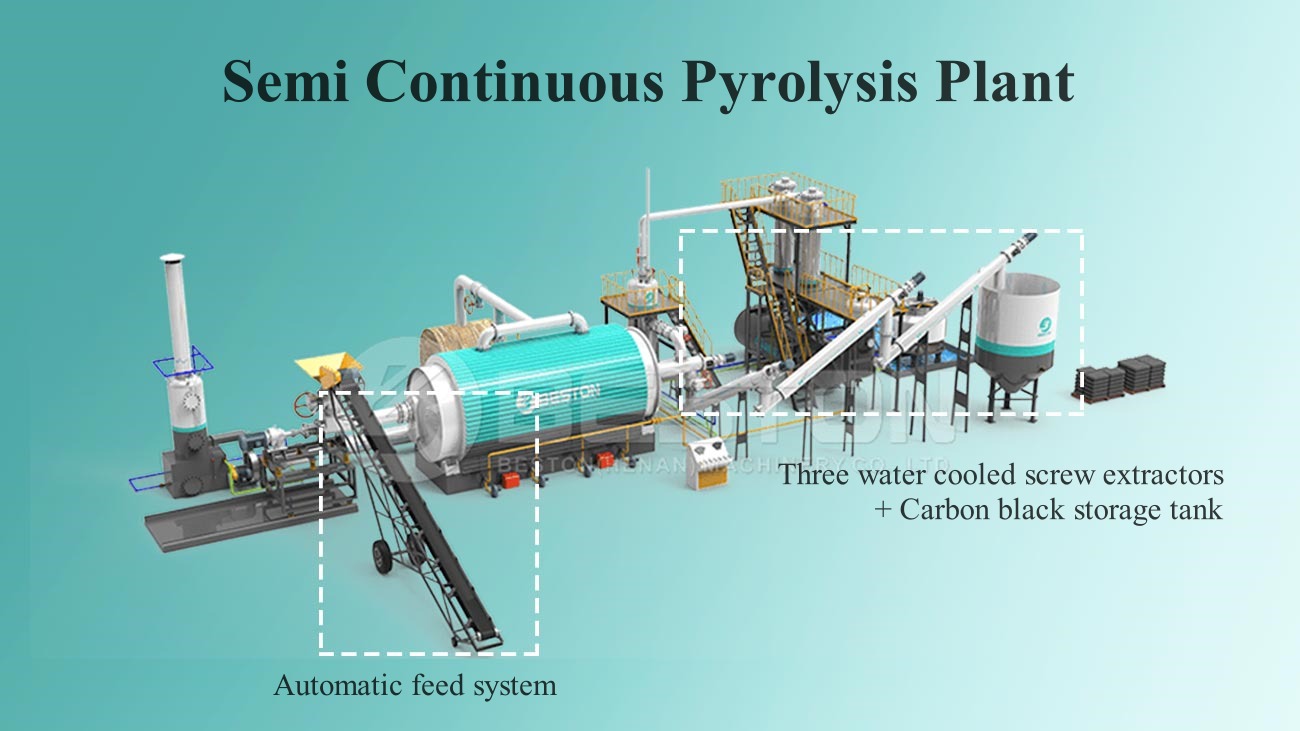

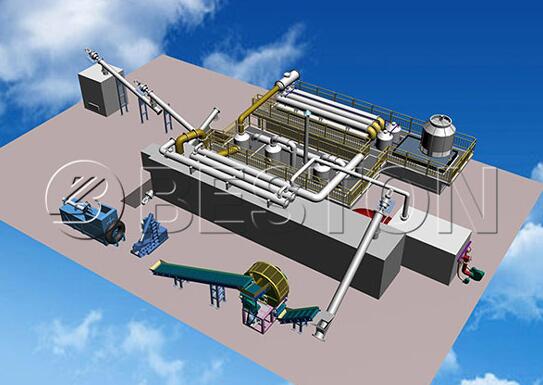

- Continuous Pyrolysis Plants: Designed for large-scale operations, these plants run continuously, offering higher efficiency and throughput. They require a higher initial investment but benefit from economies of scale.

Factors Influencing Pyrolysis Plant Costs

The cost of a pyrolysis plant can vary significantly based on several factors. Let’s explore these in detail:

1. Plant Capacity

The capacity of a pyrolysis plant, usually measured in tons per day, is one of the primary cost drivers. Larger plants have higher upfront costs due to the need for more extensive equipment and infrastructure. However, they often benefit from lower per-unit processing costs due to economies of scale.

2. Technology and Equipment

The technology used in the pyrolysis process and the quality of equipment significantly impact the cost. High-end equipment with advanced automation and efficiency features will cost more but can offer better performance, lower maintenance, and higher output quality.

- Reactor Design: The design and material of the pyrolysis reactor can affect both the efficiency and cost. Advanced reactors that offer better heat distribution and higher resilience to wear and tear are more expensive but provide long-term benefits.

- Condensation System: Efficient condensation systems are crucial for maximizing oil yield. High-quality systems are costlier but ensure better product recovery.

3. Feedstock Type and Preprocessing

The type of feedstock (e.g., plastic waste, rubber, biomass) and the preprocessing required (e.g., shredding, drying) influence the cost. Some feedstocks may require extensive preprocessing to optimize the pyrolysis process, adding to the overall cost.

4. Location and Infrastructure

The geographical location of the plant affects pyrolysis plant costs related to land, labor, utilities, and transportation. Setting up a plant in a region with favorable industrial policies, lower land costs, and an existing waste management infrastructure can reduce expenses significantly.

5. Regulatory Compliance

Compliance with environmental and safety regulations is crucial but can add to the costs. This includes expenses related to obtaining permits, installing pollution control equipment, and conducting regular environmental impact assessments.

6. Operational Costs

Operational costs include labor, maintenance, utilities, and waste disposal. While these costs are ongoing, they are critical for the plant’s financial viability. Efficient management and automation can help reduce these expenses.

7. Financing and Insurance

The cost of financing the project, including interest on loans and insurance premiums, also plays a role in the overall cost. Securing favorable financing terms and comprehensive insurance coverage is essential for mitigating financial risks.

Breakdown of Pyrolysis Plant Costs

To provide a clearer picture, let’s break down the typical costs associated with setting up and running a plastic to oil machine:

1. Capital Expenditure (CapEx)

- Land and Site Development: Costs associated with purchasing land and preparing the site for construction.

- Plant Construction: Building the physical structure, including foundations, buildings, and access roads.

- Equipment Purchase: Costs of reactors, condensers, feedstock preprocessing units, pollution control systems, and other necessary machinery.

- Installation and Commissioning: Expenses related to installing the equipment and ensuring it operates correctly.

2. Operational Expenditure (OpEx)

- Raw Material Costs: Expenses for procuring feedstock, which can vary based on availability and transportation.

- Labor Costs: Wages for skilled and unskilled workers, including operators, technicians, and administrative staff.

- Maintenance and Repairs: Regular upkeep and unexpected repairs to ensure the plant operates efficiently.

- Utility Costs: Electricity, water, and other utilities required for daily operations.

- Waste Management: Disposal or recycling of by-products that cannot be utilized.

Estimating the Total Cost

The total cost of setting up a pyrolysis plant can range from a few hundred thousand to several million dollars, depending on the factors mentioned above. Here is an approximate cost range based on plant size:

- Small-scale Batch Plant (1-5 tons/day): $200,000 – $500,000

- Medium-scale Continuous Plant (5-20 tons/day): $1 million – $3 million

- Large-scale Continuous Plant (20+ tons/day): $3 million – $10 million+

These estimates include both CapEx and initial OpEx but can vary significantly based on location, feedstock type, and specific project requirements.

Financial Viability and Return on Investment (ROI)

Investing in a pyrolysis plant requires careful financial analysis to ensure its viability. Key factors to consider include:

- Revenue Streams: Sale of pyrolysis products (oil, gas, char), potential carbon credits, and tipping fees for waste processing.

- Market Prices: Fluctuations in the prices of pyrolysis products can impact profitability.

- Operational Efficiency: High efficiency in feedstock conversion and low downtime can enhance returns.

- Payback Period: The time required to recover the initial investment through profits, typically ranging from 3 to 7 years.

Conclusion

The cost of a pyrolysis plant is influenced by a multitude of factors, including capacity, technology, feedstock, location, and regulatory compliance. While the initial investment can be substantial, the potential for generating revenue from waste products and contributing to sustainable waste management makes pyrolysis an attractive option. By carefully analyzing these cost factors and planning accordingly, investors can make informed decisions and achieve a favorable return on investment. As the demand for sustainable solutions grows, pyrolysis technology is poised to play a crucial role in the circular economy, transforming waste into valuable resources. More information on Beston.