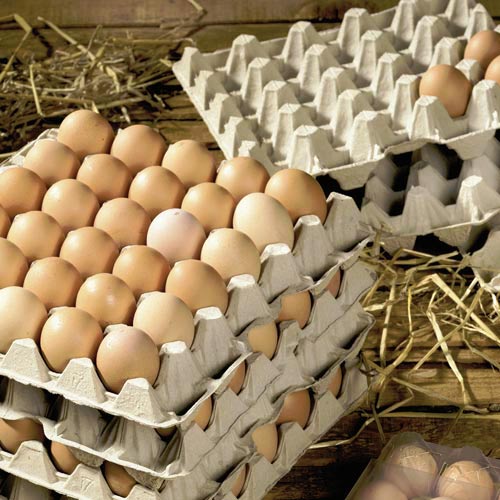

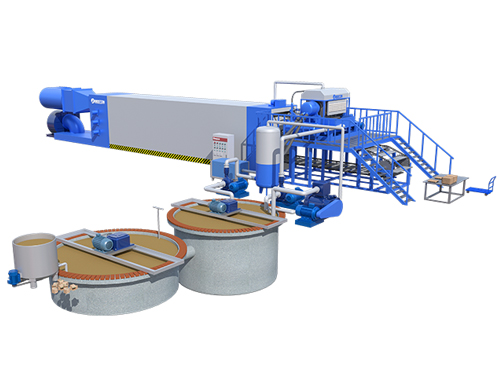

Industrial production of paper egg trays has widely gained inception, as many companies are now investing in the business. The availability of machines has made it easy for people to achieve this goal. The raw material used in this case is waste paper. It is readily available locally or from recycling firms in bulk. The egg tray machine assumes a four-step production process, including pulping, molding, drying, and packing. Manufacturing is economical since there are no wastages. It also works on an environmentally sustainable procedure by recycling the scraps with a vast potential to result in pollution. Read on to find detailed information about the stages.

Pulping Stage.

The pulping stage is the first step to manufacturing paper egg rays(производство бумажных лотков для яиц). At this level, there is sorting of the waste papers then inserting them in a water pool. The water content has to be appropriate; otherwise, the rest of the steps will be inefficient. This stage is vital as it determines the kind of output. Upon mixing with water, the pulp beater will smash the mix until it forms a consistent mixture. There is also the removal of impurities and the addition of pigments if necessary. The mixing is continuous to eliminate any chance of lumps. Once it is in the desired state, it gets conveyed to the next level.

Molding Stage.

It is the second stage where the mixture becomes molded in the desired shapes. The egg tray making machine is versatile as it can also make fruit and shoe trays alongside egg trays. The difference comes about through changing patterns on the equipment. The mixture formed in the first stage lands on the molding system through pipes. It is at this level that the operator can determine the capacity of production. At the molding stage, there are vacuum pumps and air compressors that work to ensure proper formation of the product. Also, it helps to reduce any water retained to improve the functionality at the drying stage. When the pulp takes the desired shapes, the air compressor blows them off, ready for the next step.

Drying Stage.

The drying stage helps to remove any amount of water remaining in the egg trays. Production of egg trays utilizes three different drying systems. The first is called natural drying. It takes place under the sun hence only suitable when the weather is desirable. The others include either a metal or brick drying line fitted with conveyors. Depending on production capacity, you can either opt for multi, double, or single-layered designs.

Packing Stage.

It is the finishing step of the egg tray manufacturing process. The stage makes use of a hot press to define the appearance of the egg trays. Also, it gets rid of any air trapped that would make them irregular. Lastly, they get packaged in the various boxes and ready for freight.

There are different varieties of egg tray making machines, but all work on the same principle. The process is thorough, and you can create various egg trays in terms of sizes and shapes. You can buy it here! https://www.bgenvirontech.net/