As the world continues to seek sustainable alternatives to fossil fuels, pyrolysis technology has emerged as a transformative method for converting waste into valuable resources. One company leading this innovation is Beston Group, a globally recognized manufacturer specializing in waste-to-energy equipment. With years of experience and a strong commitment to environmental protection, Beston provides customized pyrolysis oil production systems tailored to different feedstocks and industries.

1. Waste Plastic Pyrolysis Solution

Millions of tons of plastic waste end up in landfills or oceans each year, posing severe environmental challenges. To address this global issue, Beston developed the waste plastic pyrolysis plant, which efficiently converts discarded plastics into pyrolysis oil, combustible gas, and carbon black. This solution offers a profitable and eco-friendly way to recycle non-recyclable plastics such as PE, PP, PS, and ABS.

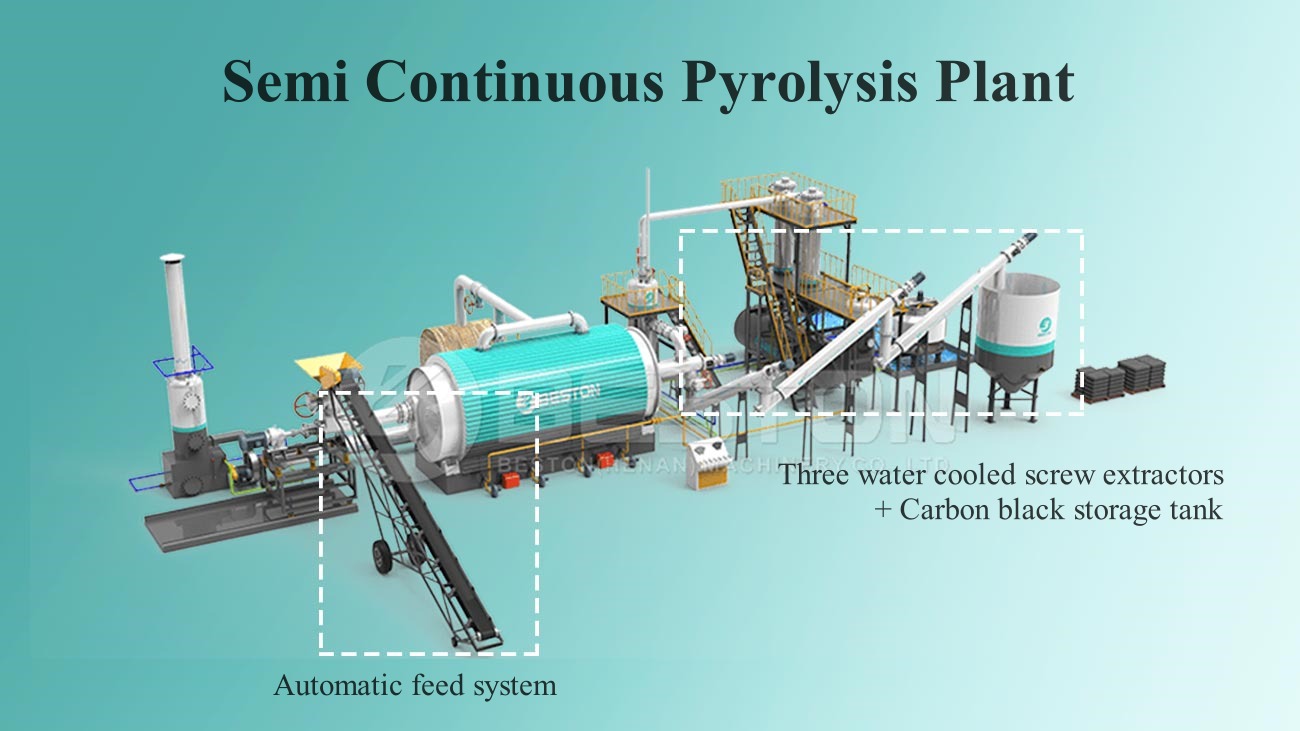

The system operates under an oxygen-free and high-temperature environment, where polymers are thermally decomposed into smaller hydrocarbon chains. The resulting pyrolysis oil can be refined further into diesel or used directly as industrial heating fuel. With Beston’s continuous feeding system and automatic temperature control, operators enjoy higher efficiency and reduced labor costs.

Moreover, Beston’s plastic pyrolysis units are designed with advanced emission control systems, including water film scrubbers and de-dusting towers, ensuring compliance with strict environmental standards. This makes it an ideal solution for both developed and developing countries seeking green technology to manage plastic waste sustainably.

2. Oil Sludge Pyrolysis Solution

Another significant environmental challenge lies in oil sludge — a byproduct generated during oil extraction, transportation, and refining. Beston’s oil sludge pyrolysis plant offers an effective treatment method that transforms oil-containing waste into recoverable oil, clean sand, and non-toxic water.

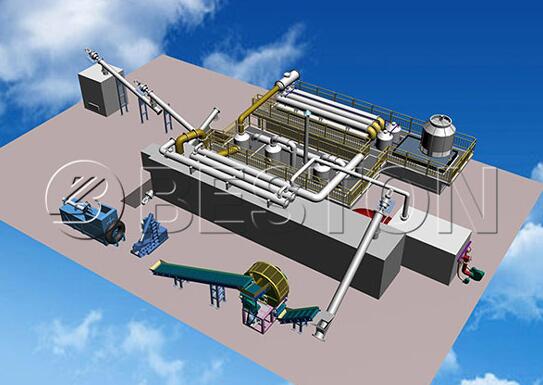

The process begins with pre-treatment, where large particles and water are separated. The remaining sludge is fed into the reactor and heated in a sealed environment. As the temperature rises, hydrocarbons vaporize and condense into high-quality pyrolysis oil, while residual solids are safely discharged. This not only recovers valuable energy but also prevents soil and groundwater contamination.

Compared with traditional incineration or landfill methods, Beston’s pyrolysis technology produces minimal emissions and offers remarkable energy recovery efficiency. The system’s modular design allows for easy installation, maintenance, and scale-up based on the project’s capacity requirements. Oil refineries, drilling companies, and waste management firms around the world have already adopted this solution to reduce operational costs and improve sustainability.

3. Rubber Pyrolysis Solution

Waste rubber, particularly used tires, has become a growing concern for urban waste management systems. Beston’s rubber pyrolysis plant is specifically engineered to recycle end-of-life tires, rubber soles, and industrial rubber scraps into pyrolysis oil, carbon black, and steel wire.

Using advanced thermal cracking technology, the plant decomposes rubber polymers at temperatures ranging from 450°C to 550°C without oxygen. The resulting oil can be utilized as an industrial fuel, while carbon black can be refined for use in pigment or rubber manufacturing industries. The extracted steel wire is also resold to the metal recycling market, providing an additional income stream.

Beston’s rubber pyrolysis systems are built with energy recovery mechanisms that reuse non-condensable gases to heat the reactor, significantly reducing fuel consumption. Additionally, its intelligent control systems allow operators to monitor the entire process through a digital interface, ensuring maximum efficiency and safety.

Why Choose Beston Group?

Choosing Beston Group means partnering with a trusted global leader in waste-to-energy solutions. The company’s mission extends beyond manufacturing; it aims to help governments, industries, and entrepreneurs achieve zero-waste goals through advanced recycling technologies. Beston offers end-to-end project support — from equipment design, delivery, and installation to operator training and after-sales service.

Their R&D team continually upgrades system components for higher oil yield, lower emissions, and longer reactor lifespan. Whether you are starting a recycling business or expanding an existing facility, Beston provides flexible configurations and capacity options to suit your production goals and budget.

Global Impact and Sustainability

Beston’s pyrolysis technologies have been exported to over 100 countries across Asia, Africa, Europe, and the Americas. By transforming solid waste into renewable fuel and recyclable by-products, these systems contribute to the circular economy and reduce dependence on crude oil. Each project represents a step toward cleaner energy and a greener planet.

Furthermore, the company’s commitment to corporate social responsibility ensures that every production line aligns with international safety and environmental standards such as CE, ISO, and SGS certifications. Clients receive not only high-quality equipment but also long-term value and operational security.

Conclusion

As environmental regulations tighten and the need for renewable resources increases, adopting advanced pyrolysis oil production technology becomes more essential than ever. With its comprehensive range of solutions for plastic, rubber, and oil sludge recycling, Beston stands out as a reliable partner for sustainable industrial growth. Through innovation, responsibility, and continuous improvement, Beston Group is helping shape a cleaner and more resource-efficient future for the world.