You need to take your time when looking for pyrolysis equipment. You don’t want to buy something that isn’t going to work well. This guide will have the tips in it that you need to know so you get the proper pyrolysis equipment for a decent enough price for it to be worth it.

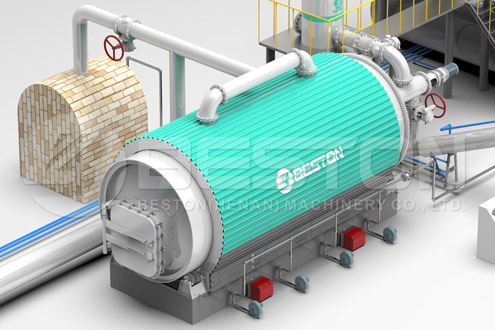

You’re going to need to buy pyrolysis equipment that is in good working order. This is why you’re going to want to ask the sellers when they got the equipment so you know if it’s new or if it has been sitting around for a while. If they got something a long time ago, you should ask them if they can test it out for you to see if it’s in good working order. If they can’t do that, then at least ask them what your options are if you get the equipment and find out it doesn’t work.

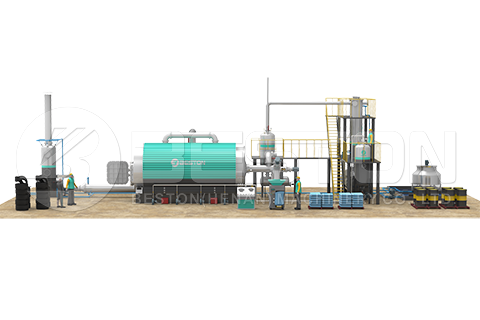

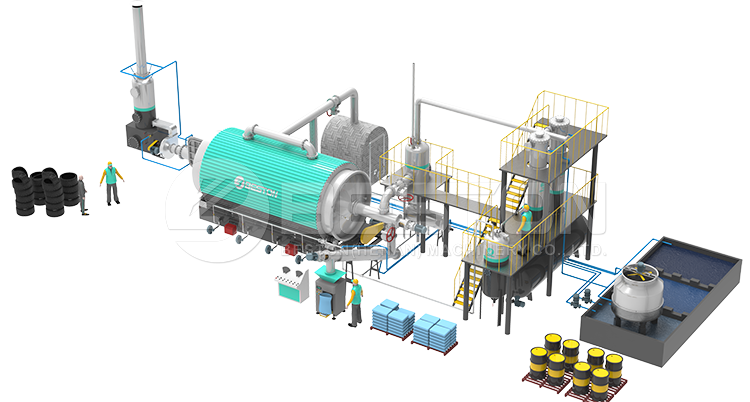

Don’t buy from a seller if you can’t return tyre pyrolysis plant for sale that you’re not happy with. If you buy something that just doesn’t do its job the right way, then you need to know that you can get some money back for it. If you can’t get anything back for it and you can’t return it to get a replacement, you’re stuck with it. In that kind of case, it may be wise to try to hire someone to fix the machine for you or to just sell it to someone for parts to try to get some of your money back. Of course, you can find pyrolysis plant project report for help.

Figure out what a good pyrolysis machine price you’re interested in getting. Find out what a few different sellers are charging for what they have to offer you. It’s important that you find a price that is fair but not something that is so low that it must mean there is something wrong with the equipment. When you find something at a very low price you need to ask the seller why it’s priced at such a low point. They may be trying to just get rid of it fast or there may be a problem with it. You never know unless you ask.

It may be wise to buy something that is used and to fix it up to get it to work well again. When you buy used, you save quite a bit of money about cost of tyre pyrolysis plant when all is said and done. But, you have to know how to fix the problem or else you then get stuck with trying to get rid of a broken machine. If you can’t fix it up then see if you can find someone in your area that is good with a solid waste management machine and can do the repair work for you.

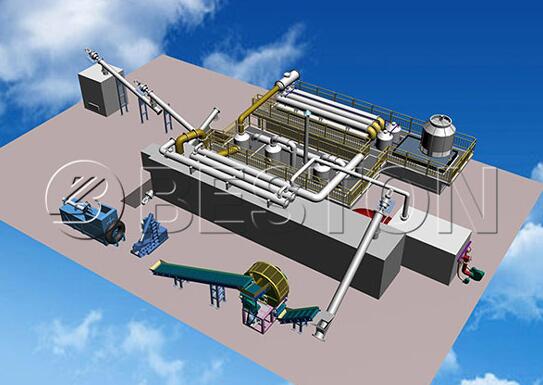

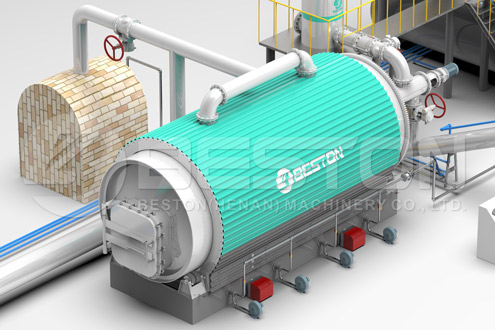

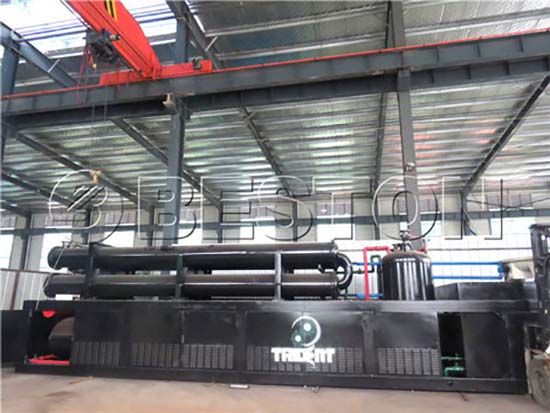

You now have an idea of what it takes to find the proper pyrolysis equipment for sale. If not, please contact Beston (China) Machinery for the latest information. In the long run, it’s good to take a moment to do your research. You’ll be glad you did when you know that you got solid equipment for a great price.