2The chicken egg market is estimated to be worth $8,4 billion in the United States during 2021 – and between 2016 and 2021 it is a market that has grown 3.2%. Eggs are a ready source of protein and have been more than just a simple breakfast staple for decades – and the use of chicken eggs in food manufacturing is steadily increasing. In essence, this means that those who are looking to maximize profits in a growing industry should be looking to invest in automatic egg tray making machine in India or other places.

These machines offer a superior return on investment for a number of reasons.

Another advantage that the automatic egg tray machine offers is that it uses recycled paper pulp from a variety of sources. This allows the material to be sourced from companies that recycle anything from old newspapers to books no longer in circulation. The availability of this material means that it is cheap – increasing the bottom line for the business that is manufacturing the trays. There is also the fact that the material is inherently environmentally friendly. This is often attractive to egg box machine suppliers that want to provide consumers with the reassurance that their products meet increasingly stringent ‘green’ regulations.

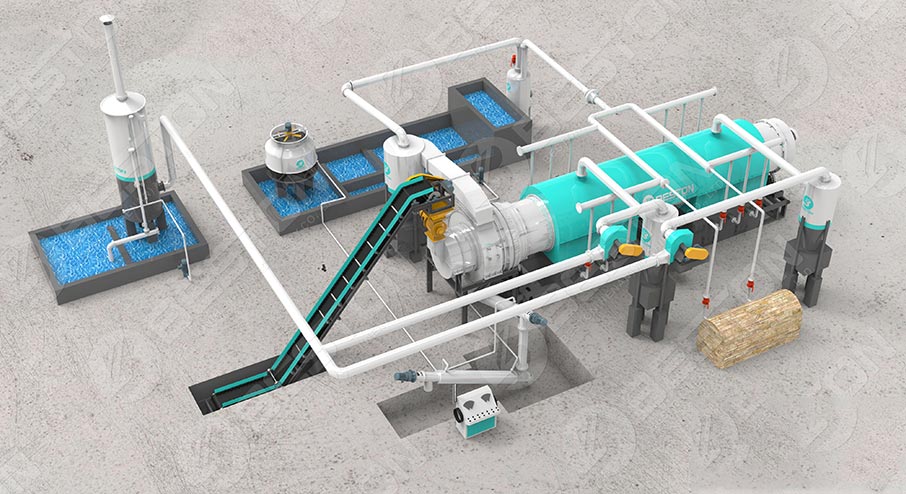

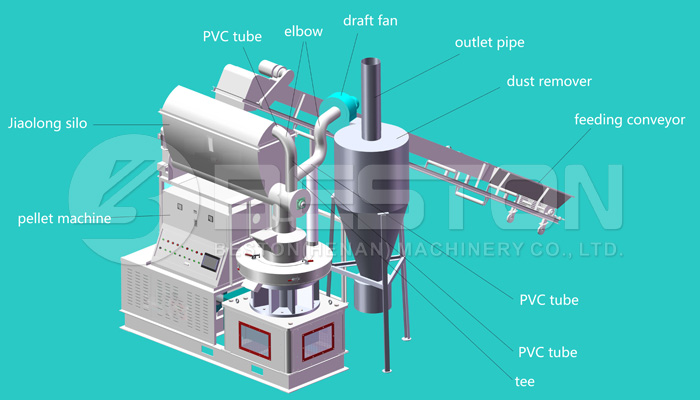

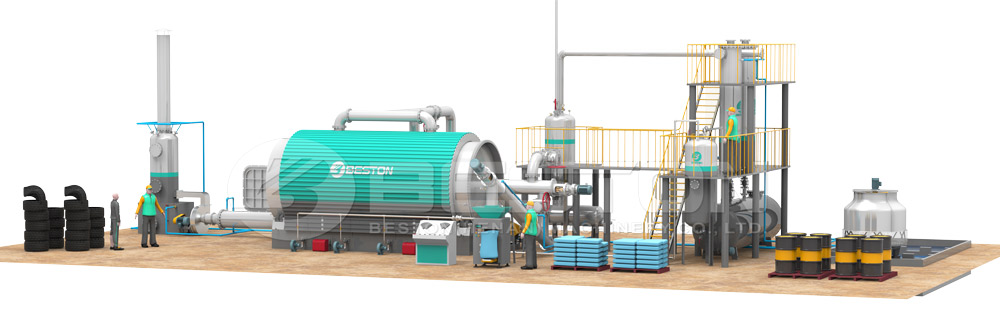

Another advantage to these machines is that they are versatile. They can be used to produce anything from bottle trays to trays used for the transportation of fresh fruit. this has implications for the profitable use of the machines. Given that they can be used for a variety of products they can be run at capacity for long hours with minimal downtime. The asset is therefore actively contributing to the profitability of the business and not standing idle for long periods. Also, Beston offers many kinds of machines for you: https://pulpmouldingmachines.com/egg-tray-making-machine/semi-automatic/.

The fully automated nature of these egg tray-making machines cuts down on the overheads of the business due to the fact that fewer workers are required during the production process. They are also highly energy-efficient and use less water (much is recycled). The fact that the trays can be configured to meet the unique requirements of each customer contributes to the profitability of the egg tray-making business.

These fully automated egg tray-making machines are ideal for use in developing countries where eggs still make up a large proportion of the daily nutritional requirements of consumers due to low cost and wide availability. The low startup costs and wide availability of the raw materials used in the manufacturing process also make them ideal for entrepreneurs who want a quick return on their investment.

Given all the above factors it is apparent that the paper egg tray machine industry will continue to show robust growth in the short, medium, and long term. An investment in a fully automated egg tray-making machine is an attractive proposition.