If you have an nursery, and you would like to get seedling trays, you can find these for sale at many different distributors. However, to save as much money as possible, you may want to make an investment into a nursery tray making machine. Some of these are designed to produce thousands of pieces per hour. The largest ones can produce 5000 or more pieces every hour automatically. To choose the right one, and also get the lowest possible price, here are some suggestions on choosing the best one for your business. Get the nursery tray making machine price.

Specifications To Consider

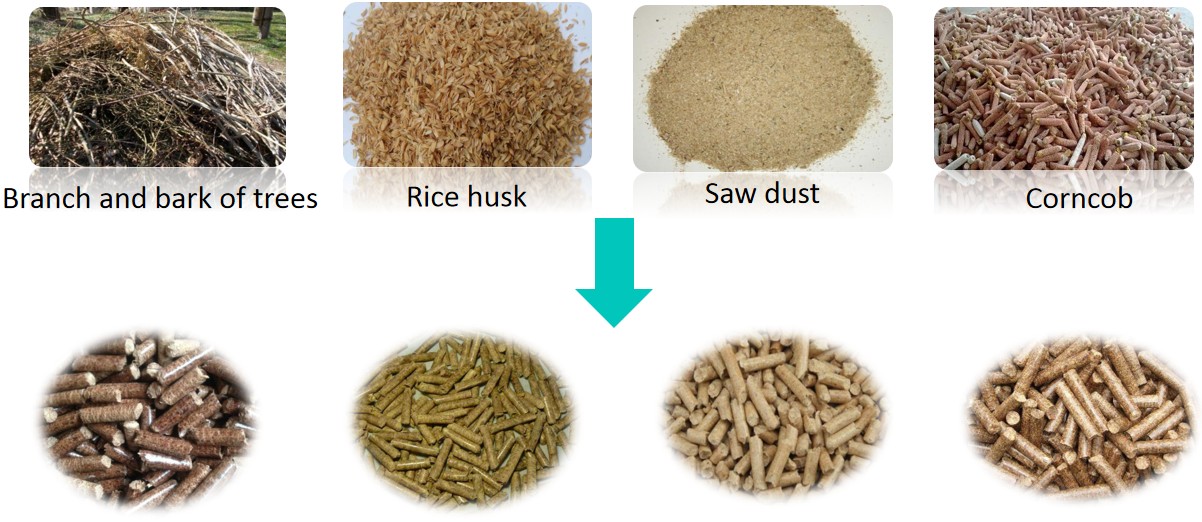

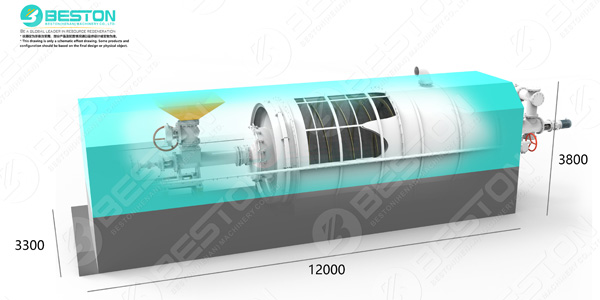

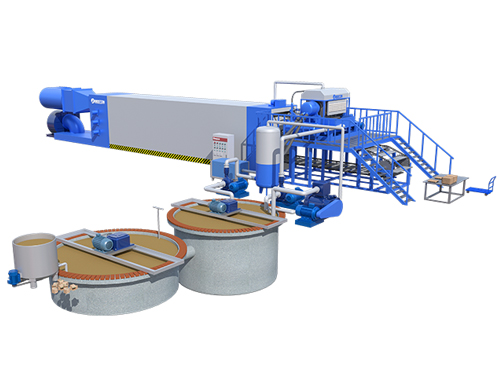

Some of the specs that you will want to pay attention to will include what type of power it uses, how much power will be necessary, and what labor force will be needed to run these competently. The electricity consumption, fuel consumption, and the type of materials that you will need will be specified when you look at this information. The materials that are necessary will include pulp, diesel fuel, water, and sometimes natural gas. After your assessment, it will be clear which one will be best suited for your business in regard to its overall cost to purchase and also operate. Remind that get a quality paper tray making machine from Beston.

How Many Of These Will You Need?

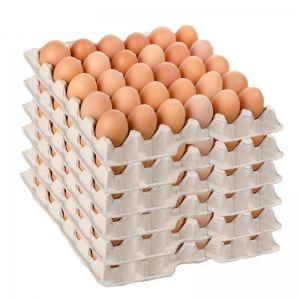

The number that you will need simply depends on the type of production you are looking for. For example, if just a thousand every hour is enough, then the smallest unit will likely suffice. Depending on the company that you are purchasing this from, you could save thousands of dollars by obtaining one from companies in the Philippines, Pakistan, and other locations. Obtaining several different estimates will help you make this decision. Also consider the length of time it will take to arrive. Once done, you will know that you are making the best decision when choosing a nursery tray making machine that will be priced to sell. Get the paper egg tray making machine price from a manufacturer now.

Are These Difficult To Set Up?

These are not difficult to set up at all. In fact, they are typically very small in size, yet they can produce more than enough for the seedlings that your business is producing. Similar to machines that produce cartons and trays for different purposes, these use the same principles when creating these materials. You will need molds of different sizes to accommodate the seedlings that you are producing with your business. Once you are done receiving and evaluating those estimates, the best one will be apparent through your research.

If you do need nursery trays for your business, instead of buying them from a wholesaler, consider making your own. It’s really not that hard to do. You should be able to find a business in your area that can sell you one, or you might want to save even more money by obtaining one from a different country. Either way, you are going to save money and have full control over the nursery trays that you produce when you are able to obtain one of these machines that you can find for an affordable price. Finally, see the details about the process https://bestoneggtraymachine.com/egg-tray-production-process/.