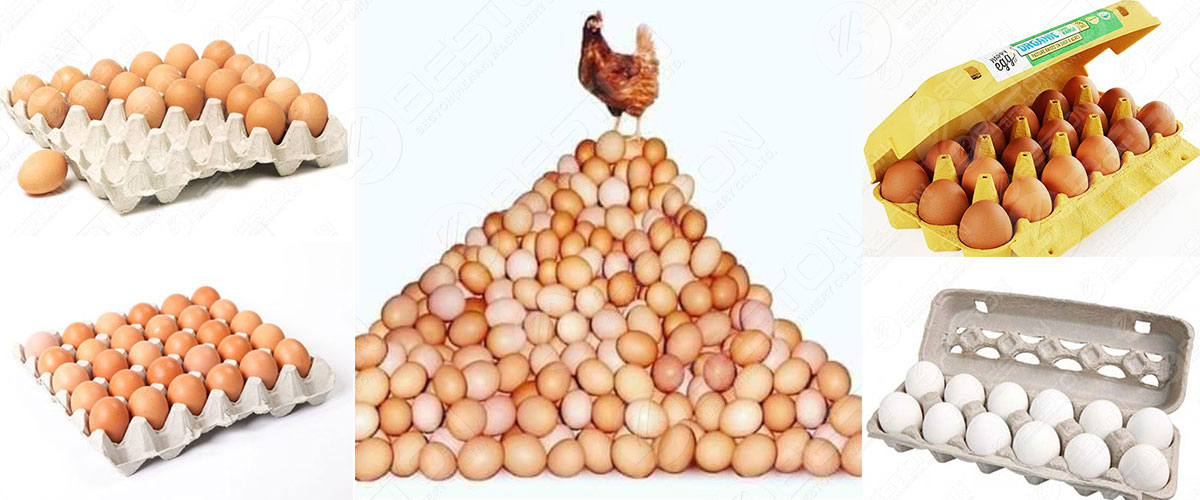

An egg tray production machine is a machine that is used to create egg trays. The egg trays are made out of paper pulp and they help to protect eggs from breaking. This type of machine typically contains a mold that determines the shape of the egg tray and a hydraulic press that forms the egg tray. The machine is an essential piece of pulp egg tray making machine for any business that produces eggs. Without it, businesses would not be able to protect their eggs from breaking and they would not be able to transport them safely.

How Does an Egg Tray Production Machine Work?

Egg tray production machines work by molding pulp into the desired shape. Pulp is a combination of water and wood fibers mixed together and then formed into trays. The trays are then placed in an oven to dry and harden. Once they are dry, they can be removed from the mold and used. egg tray production machines can produce a wide variety of egg tray sizes and shapes, depending on the mold that is used.

Things to consider when purchasing an egg tray production machine

There are a few things to keep in mind when purchasing an egg tray production machine.

1. First of all, consider the scale of production you need. Machines vary in size and output capacity, so it’s important to choose one that will be able to meet your needs.

2. Don’t forget to keep in mind the level of automation you want. Some machines are fully automatic, while others require more manual input. third, consider the cost of ownership.

3. Egg tray production machines can be costly, so it’s important to factor in the initial purchase price as well as the ongoing costs of maintenance and operation. View this machine: https://bestonmachinery.com/egg-tray-making-machine/manual/.

Types of Egg Tray Production Machine

The most common egg tray production machine is the rotary machine, designed for high-volume production. These machines can produce up to 100 trays per hour. Alternatively, a reciprocating machine can be used for lower-volume production. These machines have a lower output than rotary machines, but they are also less expensive. As a result, smaller businesses often use them for prototyping new designs. egg tray production machines can be either manual or automatic.

Manual machines require the operator to load and unload the pulp, while automatic machines can perform this task automatically. Automatic machines work faster and are more efficient than manual machines, but they also tend to be more expensive. That is why many businesses choose to use manual machines for small-scale production and save. See the egg tray machine Philippines price.

The egg tray production machine is a necessary piece of equipment for any business that produces eggs. The machine makes the process of creating egg trays much faster and easier than it would be by hand, and it also creates a more consistent product. It is a worthwhile investment for any business that wants to increase its efficiency and produce high-quality egg trays. If you are in the market for an egg tray production machine, be sure to consider all of your options and find the one that best suits your needs.