Biochar is a pyrolysis treated organic waste, which is widely used in agriculture, environmental protection and energy fields. Biochar has a variety of uses, including soil amendments, adsorbents, and energy alternatives. In order to obtain biochar that meets the requirements of a specific use, we need to adjust the process of the biochar production equipment. This article will explore how to adjust the process of biochar production equipments according to the use of biochar.

1. Understand The Use of Biochar Classification

Before starting to adjust the process of the biochar production equipment, we need to understand the main use classification of biochar. Depending on the use of biochar, it can be divided into soil amendments, adsorbents and energy alternatives. The requirements and characteristics of each use are different, and therefore need to be adjusted for different uses.

2. Adjust The Temperature and Time Parameters

The use of biochar has a direct impact on the physicochemical properties of biochar. For example, as a soil amendment, biochar needs to have good pore structure and water retention. Therefore, the pore structure and adsorption properties of biochar can be affected by adjusting the temperature and time parameters in the biochar production equipment. In general, higher temperatures and longer time will produce more porosity and adsorption activity, suitable for soil amendments of biochar.

3. Optimize The Cooling Process

In the process of biochar production, the cooling process has an important effect on the quality and performance of biochar. For certain uses, such as adsorbents and filtration materials, we need biochar with a higher specific surface area and better adsorption properties. In order to achieve this goal, the cooling method of the biomass pyrolysis plant can be adjusted. For example, using rapid cooling techniques, such as water cooling or air flow cooling, can produce biochar with more tiny pores and a higher specific surface area.

4. Select Appropriate Raw Materials and Pretreatment Methods

Different raw materials and pretreatment methods also have important effects on the use and properties of biochar. For example, as a soil amendment, biochar can use agricultural waste, wood and straw as raw materials. As an energy alternative, biochar can use biomass feedstock with high energy density. When selecting raw materials, it is necessary to consider factors such as its chemical composition, fiber structure and ash content, and select appropriate pretreatment methods, such as grinding, screening or alkali treatment, to improve the suitability and performance of biochar.

5. Customized Design and Operating Parameters

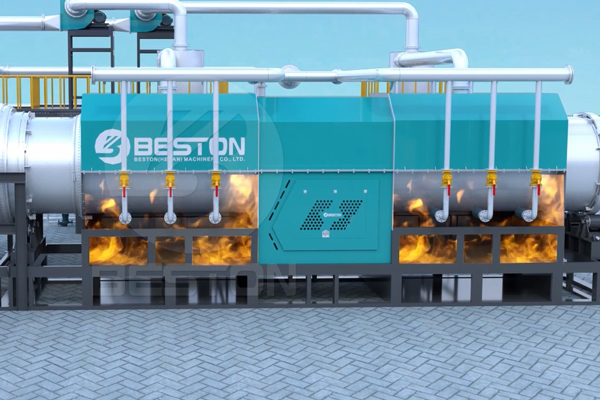

According to the needs of different uses, the design and operating parameters of the charcoal making machine can also be customized. For example, for the production of biochar for the energy sector, production equipment with a large capacity and high energy conversion rate can be selected. For the production of biochar for soil amendments, equipment with lower temperatures and longer pyrolysis times can be selected.

6. Strictly Control The Quality Management of Biochar Production

Regardless of the use of biochar, quality management is critical. By establishing a quality control system, the stability and consistency of the biochar production process can be ensured. This includes raw material testing, process monitoring and finished product inspection. Through reasonable quality management, we can obtain high-quality products that meet the requirements of biochar use.

Here to see Beston Group.