For a long time, municipalities have had to result to landfills and the incineration of the waste as the primary municipal waste management methods and technologies. However, in recent time, pyrolysis of municipal solid waste has caught on, and indeed, the technology is garnering more attention as an alternative to the methods as mentioned above of municipal waste management.

So, what is pyrolysis? Pyrolysis is the thermochemical decomposition organic waste materials under high temperatures and crucially in the absence of oxygen. In an oxygen-free environment, the organic matter undergoes a physical and chemical change that converts the organic materials into carbon-rich solid residues as well as syngas. More about pyrolysis technology: https://kingtigergroup.com/waste-pyrolysis-equipment-machinery/.

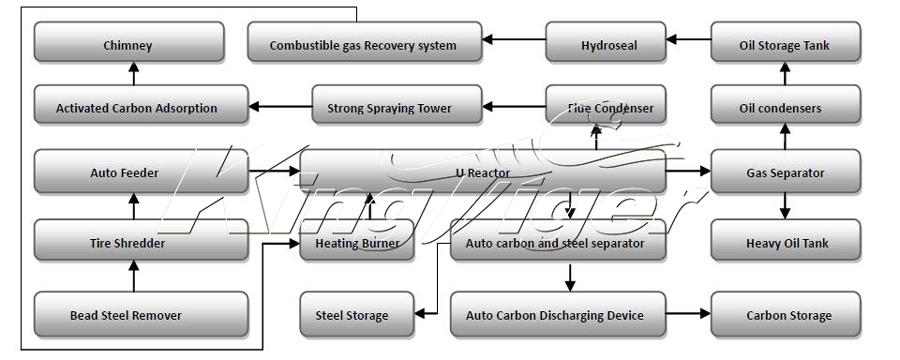

After the separation of inert materials, metals, and glasses, from the organic waste, the organic material is fed the pyrolysis reaction chamber where heating of the material in a non-reactive environment takes place. The organic materials start to decompose at a temperature range of 350°C–550°C and continues up to a temperature range of 700°C–800°C. Common types of pyrolysis reaction chambers used by municipalities include the rotary hearth, the rotary kiln, and the fluidized bed furnace designs.

Depending on the final temperature, the heat rate, and the content of the waste, the final output can either be biofuel, char (solid residue), or energy-rich gases such as methane, hydrogen, carbon monoxide.

The Benefits Of Using Pyrolysis In Municipal Waste Management

#1. It Is Energy Efficient – The end products of the pyrolysis of municipal solid waste process is include energy-rich gases and bio-oils. Municipalities can sell these energy-rich products as a source of income. An even better idea is to take the products and use them to run the pyrolysis reaction facilities. Doing so lowers the net-energy input, allowing municipalities to manage solid waste without wasting energy.

#2. Makes Recovery of Energy And Resources Possible – Unlike incineration and burying, pyrolysis allows municipalities to recover the energy trapped in the organic materials. The recovery of energy waste reduces the wastage of resources.

#3. Pyrolysis Is Far More Environmentally Friendly Than Other Forms Of Waste Management – Landfills entail simply burying the organic waste into the ground and leave mother nature to handle the decomposition. The incineration of solid waste is merely burning solid waste in an oxygen-rich environment, which results in the production and release of carbon dioxide. Both of these methods have a negative environmental impact.

On the other hand, the pyrolysis of municipal solid waste does not release carbon dioxide. Moreover, even the solid residue left from the process has utility as an input in other processes. As such, you deal with the waste conclusively, leaving behind little to no environmental impact.

#4. Municipalities Can Use This Waste Management Method On A Wide Variety Of Wastes – The solid waste that many cities have to manage consists of agricultural solid waste, non-recyclable plastics, scrap tires and much more. This method can be used to process a wide variety of these solid wastes to the oils, gases, and solid-carbons. As such, since the technology is effectively used for in managing a wide variety of organic wastes, municipalities do not need to invest in a wide variety of waste management technologies.