Biochar is a remarkable substance that holds great potential for sustainable practices. In this article, we will explore the definition and explanation of biochar and delve into the importance of its production in fostering a sustainable future.

What is Biochar Production Equipment

Definition and explanation of biochar

Biochar is a highly porous carbonaceous material that is produced through the biochar production process. This process involves heating organic biomass, such as agricultural waste or forestry residues, in the absence of oxygen. This thermally-driven decomposition process transforms the biomass into a stable form of carbon, which can then be utilized for various applications.

The resulting biochar is a solid, black substance resembling charcoal, but with distinct properties that make it invaluable for environmental and agricultural purposes. Its porous structure and high surface area provide habitat for beneficial microorganisms, making it a valuable soil amendment and a potential tool for carbon sequestration.

Importance of biochar production for sustainable practices

Biochar production plays a vital role in promoting sustainable practices across multiple sectors. It offers a range of environmental benefits, such as carbon sequestration, soil fertility enhancement, greenhouse gas reduction, and water quality improvement. Additionally, it presents economic advantages through revenue generation, cost savings in waste management, and diversification of income streams via renewable energy production.

Environmental Benefits of Biochar

Carbon sequestration and climate change mitigation

One of the significant environmental benefits of biochar is its ability to sequester carbon. By locking carbon in a stable form, biochar effectively removes it from the atmospheric carbon cycle, mitigating the adverse impacts of climate change. This carbon sequestration potential makes biochar a valuable tool in achieving global carbon neutrality goals.

Soil fertility enhancement and nutrient retention

Biochar possesses exceptional properties that enhance soil fertility and nutrient retention. When added to soil, biochar acts as a sponge, absorbing and retaining water, nutrients, and beneficial microorganisms. This promotes healthier plant growth, increases crop yields, and reduces the need for synthetic fertilizers. Furthermore, biochar enhances soil structure, improving drainage and reducing erosion.

Reduction of greenhouse gas emissions

Biochar made from the biochar reactor offers a two-fold advantage in terms of greenhouse gas emissions. Firstly, the process itself produces bioenergy in the form of syngas, which can replace fossil fuels, thereby reducing carbon dioxide emissions. Secondly, the application of biochar to soil sequesters carbon, preventing it from being released back into the atmosphere as carbon dioxide or methane, both potent greenhouse gases.

Water quality improvement and prevention of nutrient runoff

When applied to agricultural land, biochar helps improve water quality by reducing nutrient runoff. Nutrients, such as nitrogen and phosphorus, are crucial for plant growth but can be detrimental when they leach into water bodies, leading to harmful algal blooms and eutrophication. Biochar acts as a filter, adsorbing and retaining these nutrients, preventing their entry into water systems and preserving aquatic ecosystems.

Economic Advantages of Biochar Production

Revenue generation through biochar sales

Biochar production can serve as a viable source of revenue through the sale of biochar as a soil amendment. The increasing demand for sustainable agricultural practices has created a market for high-quality biochar products. Farmers and horticulturists recognize its value and are willing to invest in biochar to enhance soil productivity and crop yields. Entrepreneurs can tap into this growing market, generating profits while contributing to sustainable land management.

Cost savings in waste management

Biochar production also presents economic advantages in terms of waste management. Organic waste, such as crop residues, forestry byproducts, and animal manure, often requires disposal, which can incur significant costs for farmers and municipalities. However, by converting this waste into biochar through pyrolysis, these organic materials are transformed into a valuable resource, reducing the burden of waste management expenses.

Diversification of income streams with renewable energy production

Pyrolysis, the process of biochar production, generates bioenergy in the form of syngas. This syngas can be harnessed and utilized as a renewable energy source. By incorporating syngas utilization into biochar production systems, entrepreneurs can diversify their income streams and contribute to the transition to a cleaner and more sustainable energy future.

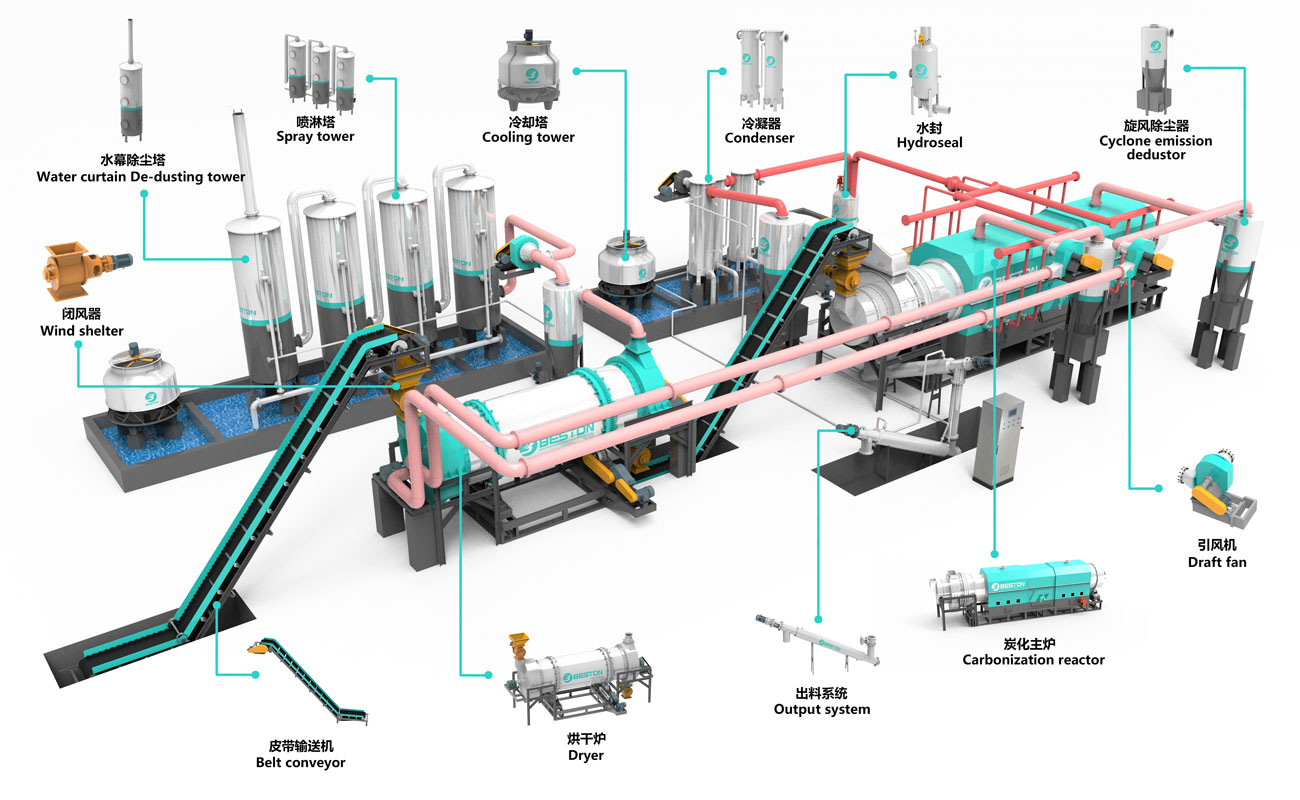

Key Components and Processes of Biochar Production Equipment

Pyrolysis reactor and temperature control systems

Biochar production equipment consists of a pyrolysis reactor, which is the heart of the system. The pyrolysis reactor facilitates the controlled decomposition of biomass into biochar, syngas, and bio-oil. Temperature control systems ensure optimal pyrolysis conditions, allowing for the production of high-quality biochar while minimizing emissions.

Feedstock preparation and sorting

To achieve consistent and efficient biochar production, proper feedstock preparation and sorting are crucial. Biomass feedstocks need to be appropriately processed, removing contaminants, such as rocks or plastics, and reducing the size to ensure uniformity. This preparation ensures optimal performance of the pyrolysis reactor and enhances the quality of the final biochar product.

Gas capture and treatment for syngas utilization

During the pyrolysis process, syngas is produced as a valuable byproduct. To harness its energy potential, efficient gas capture and treatment systems are necessary. These systems capture the syngas, remove impurities, such as tars or particulate matter, and prepare it for utilization in various applications, including electricity generation or heat production.

Emissions control for environmental compliance

Charcoal making machine must incorporate emissions control systems to ensure compliance with environmental regulations. These systems capture and treat emissions, such as volatile organic compounds (VOCs) and particulate matter, reducing their release into the atmosphere. By maintaining strict environmental standards, biochar production can continue to be a sustainable and responsible practice.

Factors to Consider When Investing in Biochar Production Equipment

Scale of operation and production capacity

Investors should carefully consider the scale of their biochar production operation and select equipment that aligns with their desired production capacity. The size of the pyrolysis reactor, feedstock handling systems, and gas treatment units should be tailored to meet the projected demands and goals of the business.

Feedstock availability and characteristics

The availability and characteristics of suitable feedstock play a significant role in biochar production. Investors should evaluate the abundance and accessibility of biomass resources in their region. Additionally, feedstock characteristics, such as moisture content, density, and chemical composition, should be considered to optimize the pyrolysis process and ensure high-quality biochar production.

Operational efficiency and automation

Efficiency and automation are essential factors to consider when investing in biochar production equipment. Advanced systems that optimize process parameters, streamline feedstock handling, and automate control mechanisms enhance production efficiency, reduce labor requirements, and improve overall system performance.

Maintenance and support services

Reliable maintenance and support services are crucial for the smooth operation of this equipment. Investors should select equipment suppliers who offer comprehensive maintenance plans, timely technical support, and access to spare parts. Regular servicing and troubleshooting assistance ensure minimal downtime and maximize the lifespan of the equipment.

Regulatory compliance and certifications

Investors must prioritize regulatory compliance and seek equipment that meets the necessary environmental and safety standards. Certifications, such as emission compliance certifications and safety accreditations, provide assurance that the equipment adheres to the required regulations, ensuring responsible and sustainable operations.

Therefore, it is important to choose a trusted supplier of biochar machines. Beston Group, as an experienced manufacturer, was a good choice.

Conclusion

Biochar production holds immense potential for promoting sustainable practices. Its environmental benefits, economic advantages, and key components and processes of production equipment make it an attractive investment for entrepreneurs. By considering factors such as scale of operation, feedstock availability, operational efficiency, maintenance support, and regulatory compliance, investors can make informed decisions and contribute to a greener and more sustainable future.