Investing in a waste pyrolysis project is a strategic decision that holds significant promise in the realms of environmental sustainability and economic profitability. Waste pyrolysis technology offers a solution to the ever-growing problem of waste management by converting waste materials, such as plastics and tires, into valuable products like pyrolysis oil, carbon black, and syngas. However, to maximize the potential of this investment, a thorough understanding of the key factors involved is essential. This article provides a comprehensive guide on how to properly invest in a waste pyrolysis project, covering crucial aspects such as selecting the right pyrolysis plant suppliers, evaluating the pyrolysis plant price, and understanding the importance of the pyrolysis reactor.

Understanding the Basics of Waste Pyrolysis

The Pyrolysis Process

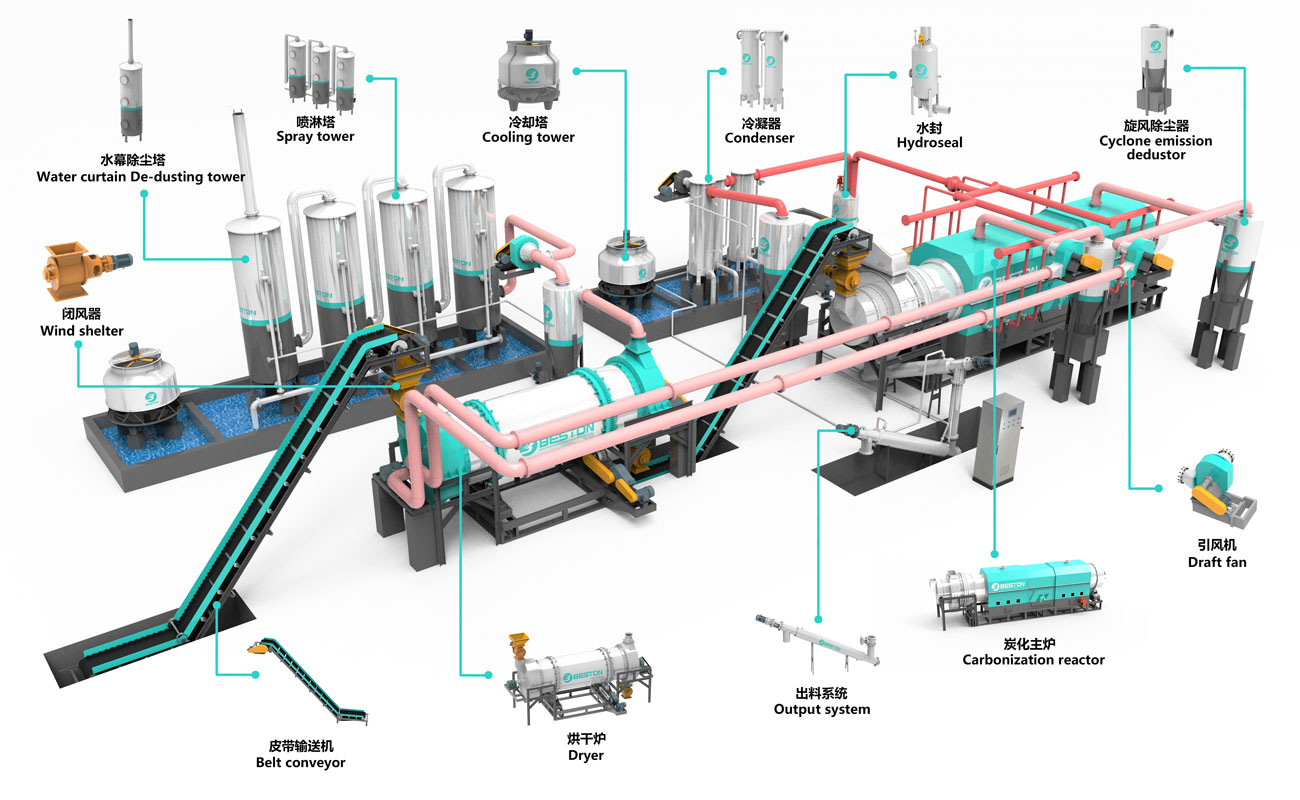

Pyrolysis is a thermochemical process that involves the decomposition of organic materials at high temperatures in the absence of oxygen. The process breaks down complex materials into simpler molecules, resulting in the production of valuable by-products such as pyrolysis oil, carbon black, and syngas. These by-products can be further processed or sold, generating revenue for the pyrolysis plant.

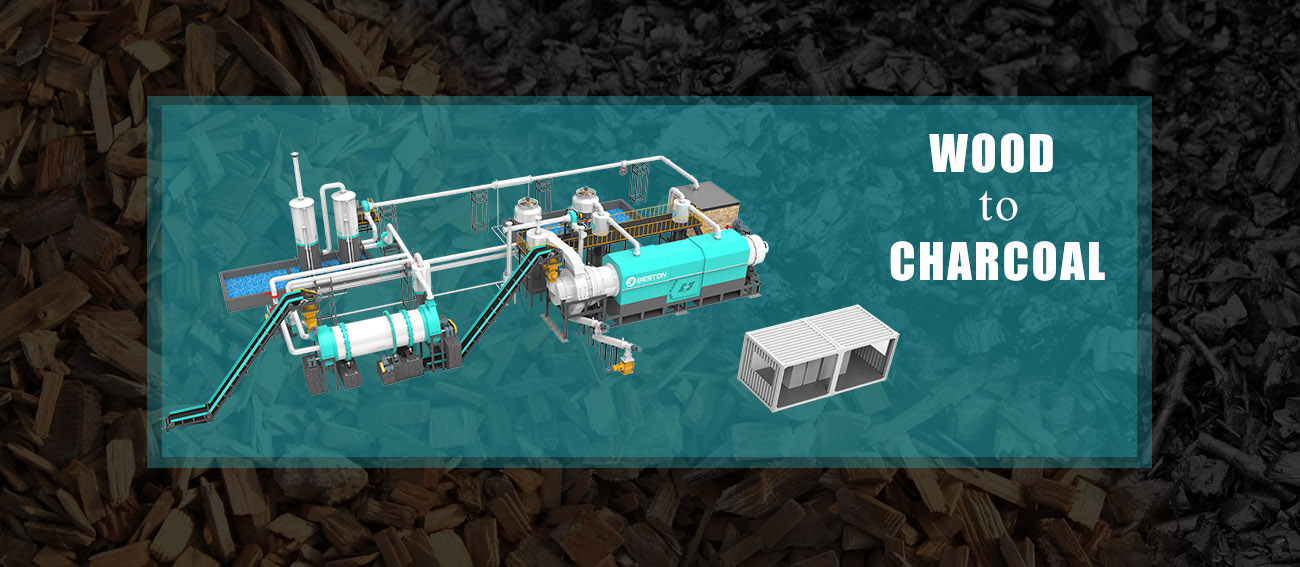

The pyrolysis process is highly versatile, capable of handling a wide range of waste materials, including plastics, tires, biomass, and municipal solid waste. This versatility makes it an attractive option for investors looking to address various waste management challenges while generating profits.

Benefits of Investing in Pyrolysis

Investing in a waste pyrolysis project offers several advantages. Firstly, it provides an environmentally friendly solution to waste disposal, reducing the volume of waste sent to landfills and incinerators. Secondly, the by-products of pyrolysis have commercial value, providing multiple revenue streams for the investor. Lastly, the technology contributes to the circular economy by converting waste into valuable resources, aligning with global sustainability goals.

Selecting the Right Pyrolysis Plant Suppliers

Importance of Choosing Reputable Suppliers

The success of a waste pyrolysis project largely depends on the quality of the equipment used. Therefore, selecting the right pyrolysis plant suppliers is a critical step in the investment process. Reputable suppliers offer high-quality equipment that ensures efficient and reliable operation, minimizing the risk of downtime and costly repairs.

When evaluating pyrolysis plant suppliers, it is essential to consider their track record and reputation in the industry. Look for suppliers with a history of successful installations and satisfied clients. Additionally, consider the level of customer support and after-sales service provided by the supplier, as this can significantly impact the long-term performance of the pyrolysis plant.

Evaluating Supplier Capabilities

Beyond reputation, it is important to assess the technical capabilities of pyrolysis plant suppliers. This includes their ability to customize equipment to meet specific project requirements, the availability of advanced technology options, and their expertise in handling various types of waste materials.

Some suppliers may offer turnkey solutions, providing everything from plant design and equipment manufacturing to installation and commissioning. Others may specialize in certain aspects of the pyrolysis process, such as the design of the pyrolysis reactor or the integration of energy recovery systems. Depending on your project needs, you may opt for a supplier that offers comprehensive services or one that excels in a particular area.

Evaluating Pyrolysis Plant Price and Costs

Understanding the Components of Pyrolysis Plant Price

The pyrolysis plant price is a major consideration for investors, as it directly impacts the project’s financial viability. The price of a pyrolysis plant is influenced by several factors, including the capacity of the plant, the complexity of the technology, and the level of automation.

When assessing the pyrolysis plant price, it is important to understand what is included in the quoted price. Some suppliers may offer a basic package that includes only the core equipment, while others may provide a more comprehensive package that includes installation, training, and maintenance services. It is essential to obtain a detailed breakdown of the costs to ensure that there are no hidden expenses.

Balancing Cost and Quality

While it may be tempting to choose the lowest-cost option, it is important to balance cost with quality. A lower pyrolysis plant price may come at the expense of inferior materials, outdated technology, or limited after-sales support. On the other hand, investing in a high-quality plant may involve a higher initial outlay but can lead to greater long-term returns due to increased efficiency, reliability, and product quality.

Consider the total cost of ownership (TCO) when evaluating the pyrolysis plant price. TCO includes not only the purchase price but also operating costs, maintenance expenses, and potential downtime. A plant with a higher initial cost but lower operating expenses may ultimately offer better value over the life of the project.

The Role of the Pyrolysis Reactor

Central Component of the Pyrolysis Plant

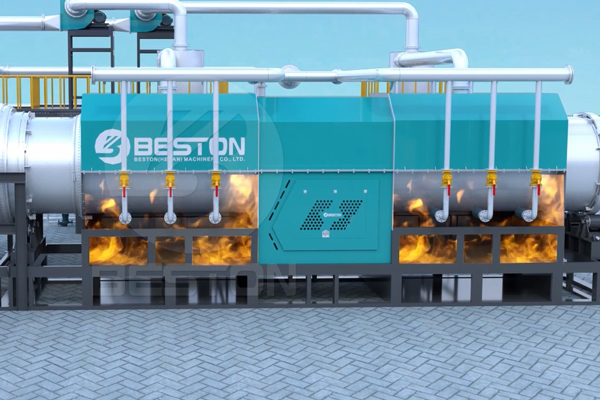

The pyrolysis reactor is the heart of any pyrolysis plant. It is within the reactor that the thermal decomposition of waste materials takes place, making it a critical component that directly influences the efficiency and effectiveness of the entire process. The design and construction of the pyrolysis reactor play a significant role in determining the quality of the end products and the overall operational efficiency.

When selecting a pyrolysis reactor, it is important to consider factors such as the reactor’s material of construction, heating method, and feedstock compatibility. A well-designed reactor will ensure uniform heating, complete decomposition of waste materials, and minimal emissions, contributing to the overall success of the project.

Types of Pyrolysis Reactors

There are several types of pyrolysis reactor, each with its own advantages and disadvantages. The most common types include batch reactors, continuous reactors, and rotary kiln reactors.

- Batch Reactors: These are ideal for small-scale operations and offer flexibility in handling different types of feedstock. However, they require manual intervention between batches, leading to higher labor costs and lower throughput.

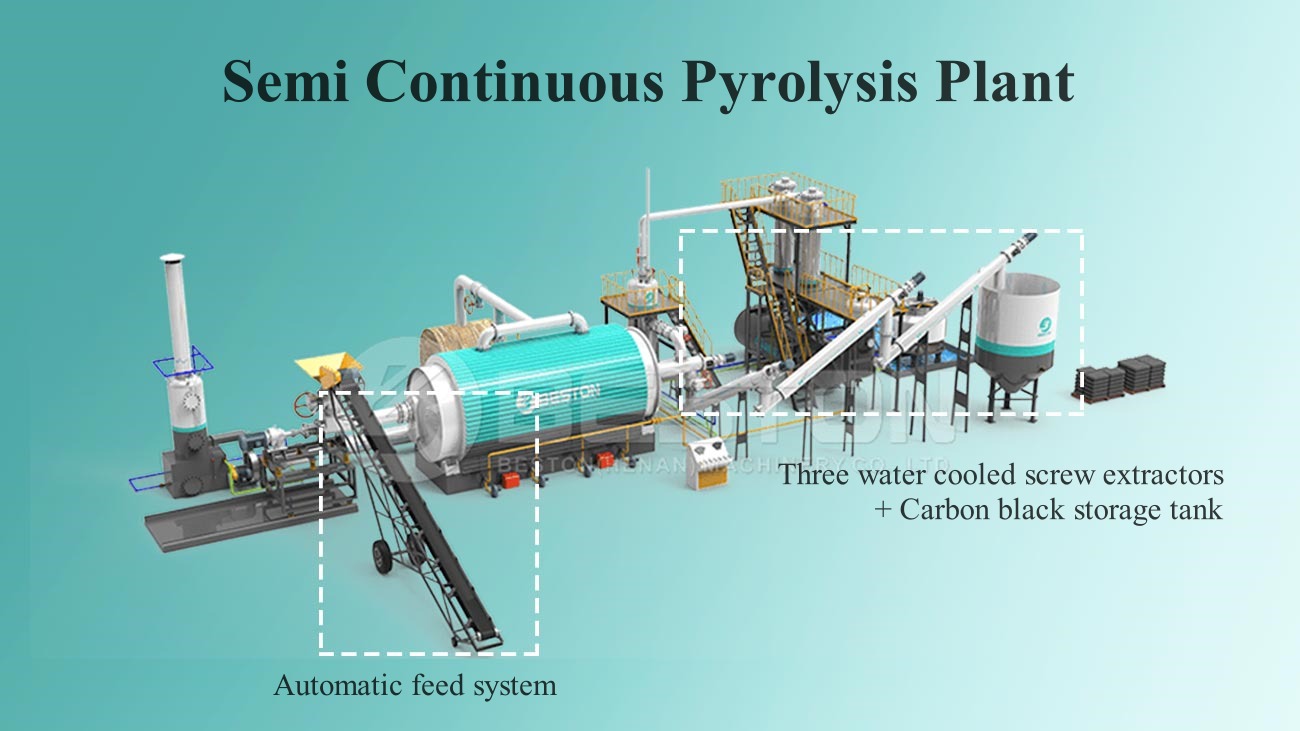

- Continuous Reactors: These reactors are designed for large-scale operations and offer the advantage of continuous feed and product removal, resulting in higher efficiency and throughput. They are typically more complex and expensive but are well-suited for high-volume waste processing.

- Rotary Kiln Reactors: Rotary kiln reactors are commonly used for pyrolysis of solid waste. They offer good mixing of feedstock and uniform heat distribution, but their design and operation can be more complex compared to other reactor types.

Choosing the right type of pyrolysis reactor depends on the scale of your project, the type of waste material to be processed, and your specific operational requirements.

Financial Planning and Risk Management

Developing a Comprehensive Business Plan

A well-thought-out business plan is essential for securing funding and ensuring the success of your waste pyrolysis project. The business plan should include a detailed market analysis, financial projections, and a clear strategy for sourcing feedstock, selling by-products, and managing operational risks.

Include a thorough analysis of the pyrolysis plant price, expected revenue streams, and projected return on investment (ROI). The plan should also account for potential risks, such as fluctuations in feedstock availability, changes in regulatory requirements, and market demand for pyrolysis by-products.

Securing Financing and Investment

Securing financing for a waste pyrolysis project can be challenging, especially if the project involves significant capital expenditure. It is important to explore various financing options, including loans, grants, and partnerships with other companies or investors.

Some pyrolysis plant suppliers may offer financing options or assist in securing funding through their networks. Additionally, government incentives and subsidies for waste management and renewable energy projects may be available, helping to reduce the initial investment burden.

Mitigating Risks

Investing in a waste pyrolysis project involves certain risks, including technological, operational, and market risks. It is essential to develop a risk management strategy to mitigate these risks and protect your investment.

Technological risks can be minimized by choosing reliable pyrolysis plant suppliers and investing in high-quality equipment. Operational risks can be managed through proper training, maintenance, and contingency planning. Market risks, such as fluctuations in the price of pyrolysis by-products, can be addressed by diversifying revenue streams and establishing long-term contracts with buyers.

Regulatory and Environmental Considerations

Compliance with Environmental Regulations

Waste pyrolysis projects are subject to strict environmental regulations, which vary by region and country. It is important to understand the regulatory requirements in your area and ensure that your pyrolysis plant complies with all applicable laws and standards.

Environmental compliance involves obtaining the necessary permits, conducting environmental impact assessments, and implementing pollution control measures. Non-compliance can result in fines, legal action, and damage to your company’s reputation.

Sustainability and Corporate Social Responsibility

Investing in a waste pyrolysis project offers an opportunity to contribute to environmental sustainability and corporate social responsibility (CSR) initiatives. By converting waste into valuable resources, your project can reduce landfill waste, decrease greenhouse gas emissions, and promote the circular economy.

Incorporating sustainability goals into your business strategy can enhance your company’s reputation, attract environmentally conscious investors, and create a positive impact on the community. Consider partnering with local organizations, governments, or NGOs to further amplify the social and environmental benefits of your project.

Conclusion

Investing in a waste pyrolysis project requires careful planning, thorough research, and strategic decision-making. By selecting the right pyrolysis plant suppliers, evaluating the pyrolysis plant price and total cost of ownership, and choosing a suitable pyrolysis reactor, you can maximize the success and profitability of your investment. If you want to find a professional supplier for consultation, Beston Group is a good choice.

Additionally, it is important to develop a comprehensive business plan, secure financing, and implement risk management strategies to protect your investment and ensure long-term sustainability. With the right approach, a waste pyrolysis project can offer significant environmental and economic benefits, contributing to a cleaner, more sustainable future.